Plastering is perhaps the most integral aspect of any construction endeavor. This process is instrumental in maintaining a building’s structural integrity while also making sure it looks aesthetically pleasing. While plastering is important, people often find themselves confounded with the prospect of choosing the ideal type of plaster for their job.

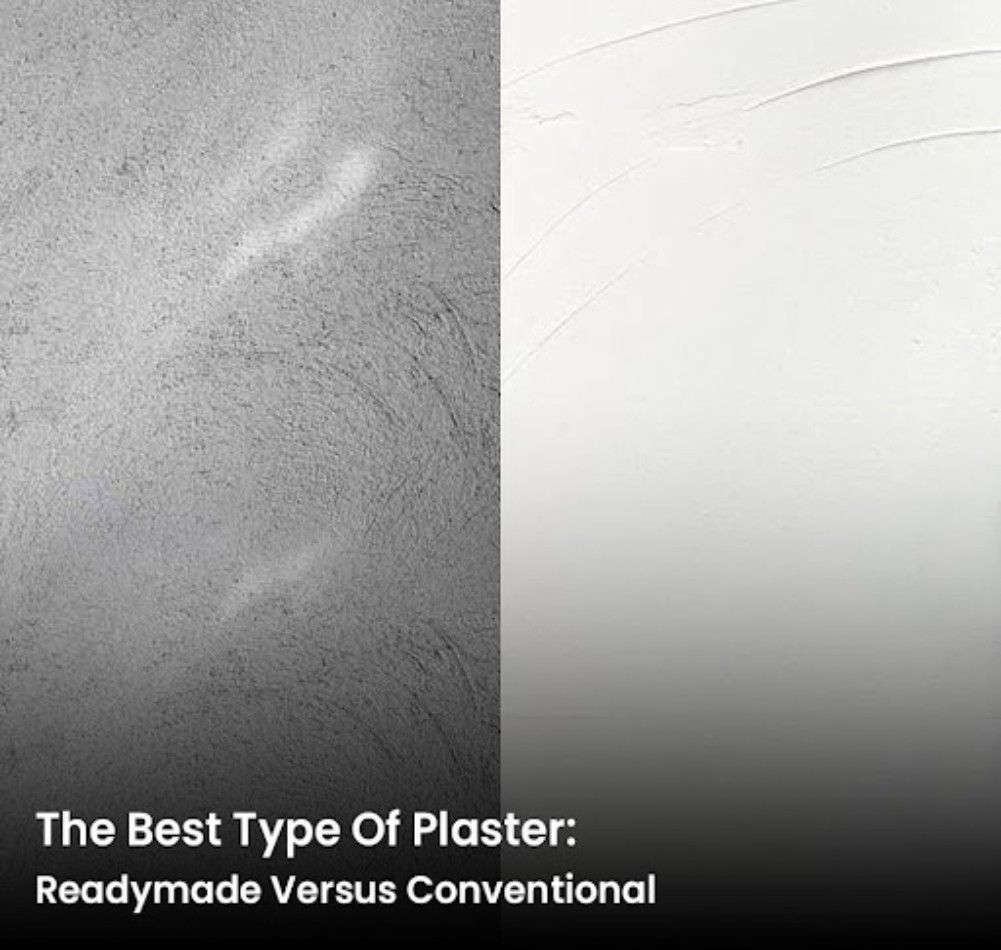

When it comes to plasters, it ultimately boils down to either ready made plaster for walls or their conventional counterpart. Needless to say, each of these options has its fair share of merits and demerits.

That said, you need to make the right choice, as the success of your entire construction project might hinge on the type of plaster you ultimately adopt.

In this article, we’ll shed some much-needed light on both of these plasters. We’ll share the pros and cons associated with each and finally let you decide which option to choose.

Ready Mix Plasters Explained

Also known as pre-mixed or ready-made, ready-mix plasters are known for their pre-packed nature. As the name suggests, these plasters come ready to use right out of the bucket. They contain ingredients like sand, water-retention agents, gypsum, and other notable additives. You can find them in the market in various formulations.

In hindsight, these types of plasters are ideal for decorative finishes, exterior rendering, and interior walls.

Conventional Plasters Explained

Also known as traditional or site-mixed plasters, conventional alternatives are usually made by blending dry ingredients. They are usually a mixture of sand, cement, and water. The proportion of these ingredients will vary depending on the specific requirement of a project.

Conventional plasters have been used since time immemorial and are popular for offering customizable benefits.

Now that you are familiar with both of these plasters, let’s dive deeper into the topic and assess each on the basis of a few key parameters.

1. Ingredient Quality

| Conventional Plaster | Ready Mix Plaster |

| Sand procured from river beds, thus containing impurities. | Sand in ready-mix plaster is clean and fine-graded. |

| More susceptible to cracks and other forms of defects | Excellent compactness and strength, thanks to the graded sand. |

While conventional plasters entail a blend of multiple ingredients, the main ingredient used in most is sand. Conventional plasters possess sand that is procured from river beds. As such, this sand might not be pure. It is very common to find slits and other forms of impurities in this type of plaster. More often than not, this sand is not graded.

Ready-mix plasters, on the other hand, feature fine-graded sand, polymer additives, and fly ash. This graded sand contributes to the bonding strength of the plaster. So, for obvious reasons, ready-mix plasters have a clear edge over their conventional counterparts.

As ready-made plasters use graded sand, you can expect relatively better strength and compactness from them, which is not possible with conventional alternatives.

2. The Handling and Mixing of Material

| Conventional Plaster | Ready Mix Plaster |

| Loose ingredients | Ingredients come pre-mixed. |

| The quality of ingredients will vary. | Quality of Ingredients is standard. |

| Difficult to handle as you’ll need to mix ingredients at site | Convenient to handle as the solution comes pre-mixed. |

Ready-mix plasters are ready to use. All you have to do is add water before application. As the proportion of the ingredients in a ready-mix plaster does not vary, you’ll have no issue maintaining it. As such, you can expect a top-notch plaster when it comes to quality.

With conventional plasters, the ingredients are procured separately, which means that the quality of each ingredient will vary. You or your labor will mix the ingredients on-site before application. It can be very challenging to maintain ingredient proportions. You’ll also need to pay extra to hire labor who’ll be in charge of mixing and shifting the ingredients.

Needless to say, when it comes to handling and mixing ingredients, ready-mix plasters are far more convenient than their conventional alternatives.

3. Ingredient Wastage

| Conventional Plaster | Ready Mix Plaster |

| Very high wastage of ingredients like sand. | Generates less wastage as it easy to store. |

As we mentioned before, the material in ready-mix plasters comes pre-mixed. You won’t have any issue storing or conveying it to the site for application. As the hassle of mixing is completely absent with ready-mix plasters, you won’t have to pay additional labor charges. This also means less wastage of material.

On the contrary, storing conventional plasters can be a challenge due to the loose nature of their ingredients. Ingredient wastage is a major issue with traditional plasters, which is why many construction experts are now moving away from them.

4. Ease of Use

| Conventional Plaster | Ready Mix Plaster |

| Very challenging to apply | Easy to apply |

| High rebound wastage | Low rebound wastage |

| Curing can take up to 7 days | Curing is over within 3-4 days. |

Most ready-mix plasters today are the result of stringent research and development. They feature ingredients like polymer-based additives that enhance their strength and facilitate strong bonding. They are also very easy to use and quick to apply, and rebound wastage with this type of material is also very low.

On the other hand, the adhesion strength of conventional plasters is very weak. You’ll have a very tough time applying it, especially if you are a novice. The rebound wastage associated with conventional plasters is also very high. Plus, this type of plaster can take a very long time to cure. Sometimes the curing period can be as long as 7 days.

5. Cost

With conventional sand cement-based plasters, procuring the actual material might not cost you much. However, you must take other factors into consideration to know how much it will end up costing you in the long run. As we said before, mixing such plasters is a time and labor-intensive practice.

You will need skilled labor for proper mixing of such plasters, which will end up boosting your expenses.

With ready-mix plasters, on the other hand, buying the actual product may be expensive but you are going to save a lot of time and money on labor. As this material comes pre-mixed, there is no need to waste time and effort in mixing on-site. Ready-mix plasters also ensure strong adhesion and consistent quality.

This means you won’t need to pay extra down the road for repairs or touch-ups, which will save you more money in the long run.

Ready-Mix Plasters VS. Conventional Plasters: Which is Better?

Depending on what we discussed above, here is how ready mix plaster fares against conventional alternatives.

| Ready Made Plasters | Conventional Plasters | |

| Ingredient Quality | Uses fine-graded sand resulting in stronger bonding strength | Uses loose sand, which results in weaker bonding strength. |

| Application Time | Quick to apply | Longer time to apply |

| Wastage | Low | High |

| Rebound Wastage | Low | High |

| Material storage | Easy | Difficult |

| Shrinkage Cracks | Negligible | Very High |

| Labor intensive | Low | High |

| Consistency | High | Low |

Conclusion

As you can tell, ready-mix plasters far outweigh conventional sand-cement-based plasters in every metric. Ready-mix plasters are easier to apply, quicker, ensure strong bonding strength, are less labor intensive, and will require little to no maintenance down the line. So it makes sense that ready-mix plasters are now widely used for renovation and construction projects.

They are simply too convenient and economical to ignore. You’ll have no issue finding ready-mix plaster suppliers in the market today. However, finding quality material from a reputable vendor can be a bit challenging unless you are looking in the right place.

If you need high-end ready-mix plasters made using eco-friendly practices, then we suggest you look no further than Magnus Ventures. We offer easy-to-use ready-mix plasters that stand out for their superior strength and excellent bonding.

Call Magnus Ventures now to learn more about the product.